On the morning of September 19, 2019, Dongguan Yongneng Electronics Co., Ltd. held the launching conference of JINGGON Cloud MES project, which formally took the road to digital transformation. More than 20 people, including general manager of Yongneng Hu and other managers, team members and project teachers, participated in the launching conference.

jinggon cloud MES achieves on-line production scheduling, real-time task delivery, workshop timely response to production, improve production efficiency, establish quality monitoring system, improve product quality, establish workshop management data by optimizing production management process. As Yongneng Hu said in his speech at the meeting, he hopes to see the production progress and product quality of each product very conveniently, and in abnormal circumstances. When it happens, it can effectively control and make decisions quickly. I hope the start of this project can bring a qualitative leap to the company.

Mr. Yongneng Hu delivered a speech at the meeting

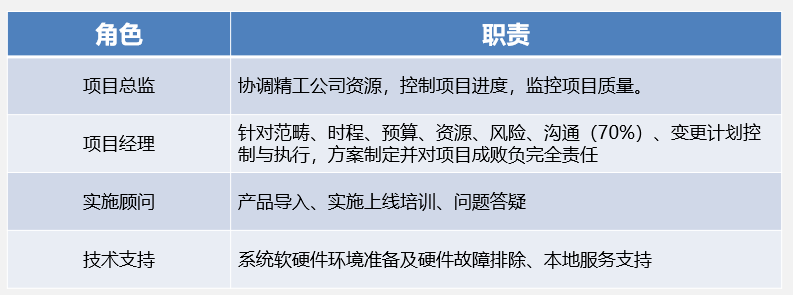

project organization

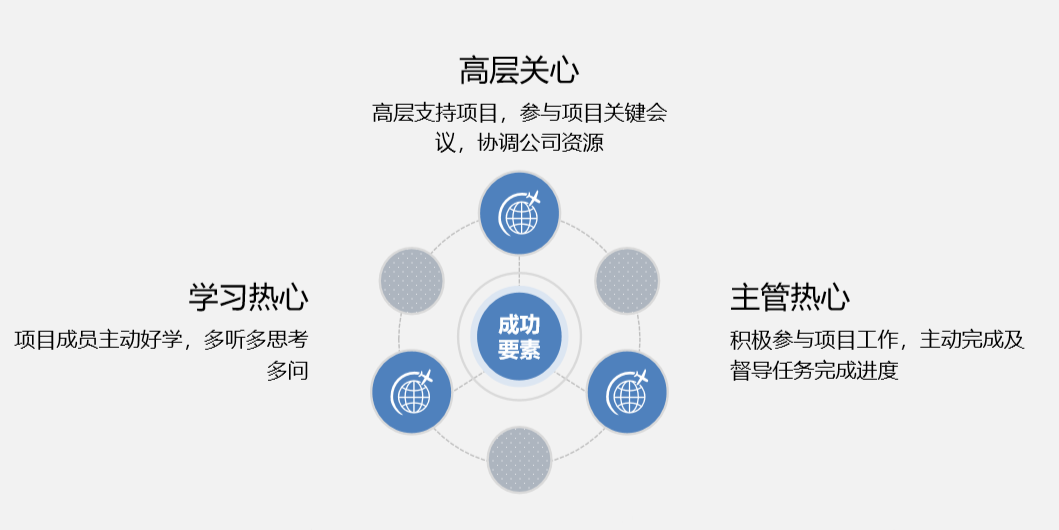

Key elements

Mr. Zhu emphasized that the key to the implementation of the whole project lies in the "coordination" of all departments, and the concern and support of all senior and supervisors. He hoped that everyone would participate actively and step by step in the same way. He also hoped that the relevant departments would cooperate actively, offer suggestions and make joint efforts for the project on-line.

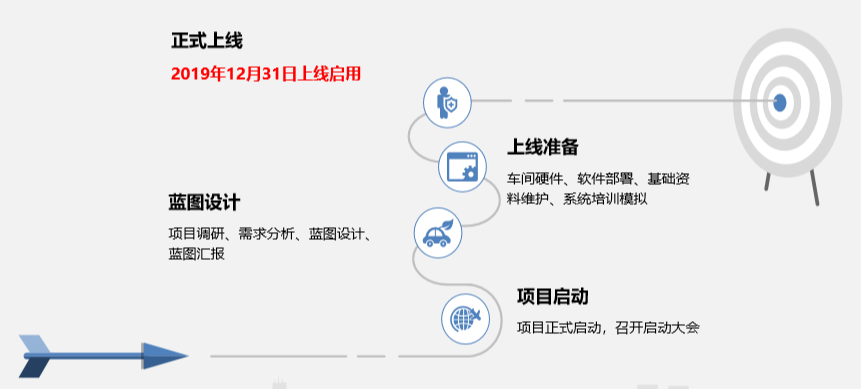

Cloud MES was officially launched and implemented on the day of the launch meeting. It is planned to start trial operation at the end of November. After a month of trial operation and acceptance, it will be officially launched on December 31.

The project includes on-line scheduling, on-line dispatching, production Kanban, SOP operation instruction, on-line reporting, data acquisition of workshop management data equipment and other modules. The preliminary results are as follows:

1、Transparency of workshop production management, scheduling tasks, dynamic visualization of production progress and visualization of quality situation。

2、Electronic production operation instructions, synchronous production task online display, reduce operation errors, improve the yield.

3、On-site collection of inspection data, generation of quality inspection statistical data system, and improvement of quality control.

4、On-line delivery of production tasks, system communication, improve the execution rate of workshop plans, improve the ability to handle abnormal orders.

jinggon Yu always said that the cloud MES project is a challenge as well as an opportunity. The market is changing, and it also needs to change itself. Only by accepting the change, can we keep pace with the times.

Yongneng Hu concluded that being a business and a person is the same as "three looks, seven dresses"”, The implementation of this cloud MES project is a bright spot for Yongneng. I hope you will spare no effort to wish the project a complete success and go online as soon as possible.

For manufacturing enterprises, realizing digital transformation is not only the most complex, but also the most vital challenge. Digital transformation is a long-term strategy, without sustained support, it is difficult to succeed. Next, JINGGON project team members and Yongneng will start to implement specific planning plans, in accordance with the plan to promote the quality and quantity of the project. The starting gun has been fired, and the Eternal Electron is speeding up the start.

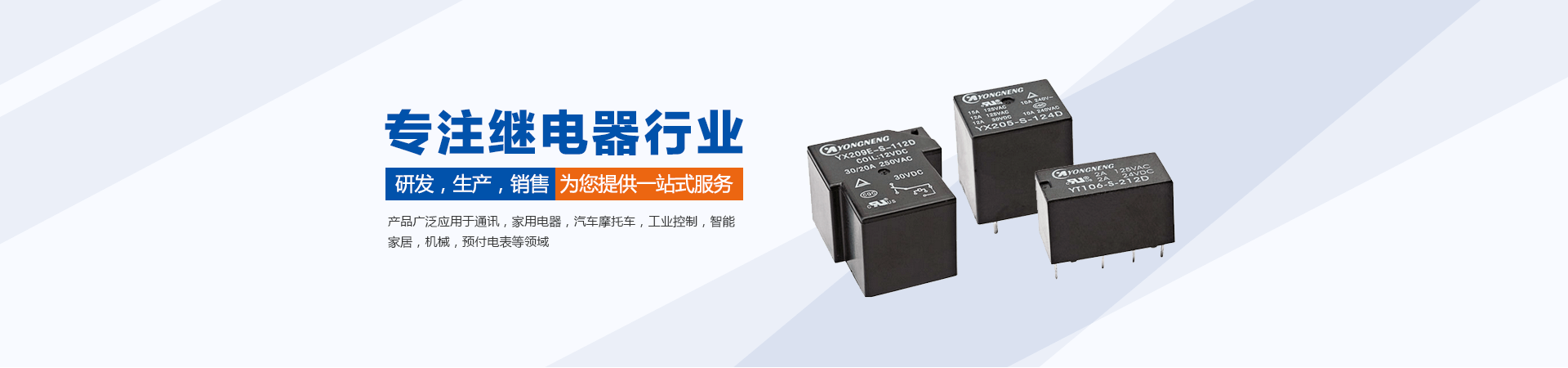

Dongguan Yongneng Electronics Co., Ltd. is a high-tech enterprise specializing in R&D, production and sales of relays. The company's products are widely used in household appliances, automation control, smart home and new energy fields. Through more than ten years of unremitting efforts and the support and trust of our customers, Yongneng's development speed and supporting capacity have reached the industry's leading level.

Yongneng has a first-class management, technology and service team, which can customize differential relays for different customers. At the same time, it has a modern production base, producing more than 20 series and 800 kinds of relays of common specifications, with an annual production capacity of 150 million. Establish offices and after-sales service network in many places. It has the ability of global market operation and technical service.

Yongneng Appearance

The company passedISO9001:2015andISO14000:2015及IATF16949:2016Quality management system certification, and passed the European UnionROHS、REACH指Make the test requirements. The products have passed successively.UL、CUL、TUV、CQC、CESafety and safety certification. Reliable quality assurance, perfect technical services and the best cost-effective, has been recognized and appreciated by customers at home and abroad.

Yong Neng products

微信公众号

乐鱼视频号

乐鱼抖音号

全国统一热线:400-696-6999

广东公司:Jinggong Zhizao Digital Intelligence Industrial Park, Baohui Road, Lunjiao, Shunde District, Foshan City, Guangdong Province, China.

13077439821 屈老师

浙江公司:浙江省宁波市江北区前洋E商小镇北门一号楼414室

13077439821 屈老师

江苏公司:江苏省无锡市梁溪区清扬路333南长创业大厦603

13077439821 屈老师

安徽公司:合肥市高新区中安创谷A3A4号楼742室

13077439821 屈老师

全国统一服务热线